DyCo5 nanostructures increase storage capacity and stability

6/17/2016, Milan Šurkala

Heat Assisted Magnetic Recording (HAMR) provides high data density but it also has its own issues like the need for very high temperatures and lower stability. New dysprosium-cobalt nanostructures will help to improve both density and stability.

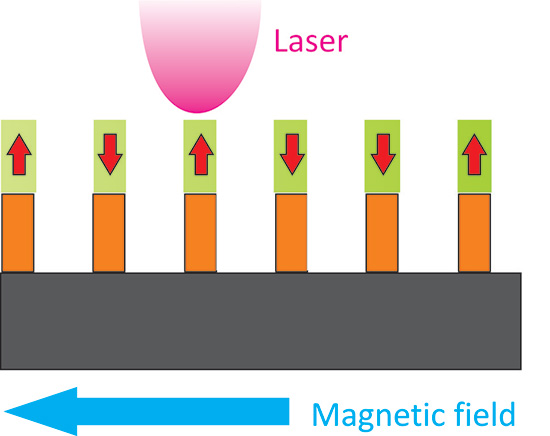

There is continuous need for higher data density that will never end. The last technology used in hard drives is Heat Assisted Magnetic Recording (HAMR) that lowers the area needed for saving one bit. This area has to be heated by laser before the storage drive can work with the data and quite high temperatures are required. Moreover, the stability of these bits tends to be lower as the size is shrinking. The researchers at Helmholtz Zentrum Berlin (HZB) have developed better technology that allows engineers to achieve even higher data density concurrently with much lower temperature requirements and improved stability.

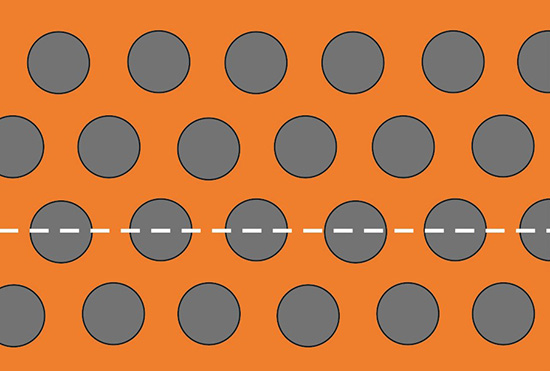

Instead of iron and platinum that is used in ordinary HAMR drives, the researchers have used materials from dysprosium and cobalt (DyCo5) and have created a nanostructured membrane with a honeycomb pattern. In this structure, nanoholes holding the information are 105 nanometres away from each other and they ore only 68 nanometres in diameter.

Magnetic moments are perpendicular to the plane and that improved their magnetic stability against external magnetic fields. When writing the information has to be done, the temperature of only 80 °C is needed (several hundreds degrees are needed in ordinary HAMR techniques). Therefore, it is more efficient and it can be even faster. It is unclear where (and if) this technology will be incorporated into consumer storage solutions.

Source: spectrum.ieee.org, helmholtz-berlin.de

.jpg)

.jpg)